Electro-etcher/plater/markerSections

IntroductionFigured I would give etching/engraving a try. Why not? I considered laser-engraving, hand-engraving (perhaps with a pantograph), acid-etching, and finally electro-etching. Once I started looking to electro-etching, I quickly discovered the related fields of electro-plating and electro-marking and become quite enthralled with all three processes. In addition to being both safer and cheaper than acid-based methods, the newer electrolytic methods are well documented online (although one must sift through an abundance of poor references to find the good ones. Hopefully, my list below will help in that regard). ReferencesThe internet is absolutely soaked in reference material on electro-etching, and to a lesser degree in material on electro-plating and electro-marking. However, by far the most comprehensive and least error-ridden (to the best of my knowledge) resource I have found is Cedric Green's website: http://www.greenart.info/galvetch/contfram.htm. This project is based on the following designs. As you will notice, this DIYization of electro-etcher/markers has been pioneered by the knife-making community, since they like to electro-mark their creations. I have found that the greater nuance and overall complexity often demanded by etching and plating are disregarded in these references since marking is their primary focus. Nevertheless, I strongly suggest reading them all before embarking on a project of your own: Electro-etching/plating/marking in general

At-home electro-etching

DIY electro-etcher building instructions

Design & Circuit DiagramMy design differs from those in the references in the following ways:

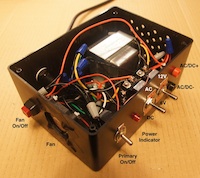

Future work would include the addition of a potentiometer to the DC circuit to gain better control over the voltage and the addition of a voltmeter and ammeter to enable monitoring of the power characterics. One could also add a smoother capacitor to the DC circuit. I didn't bother because it isn't really necessary for electro-etching and plating. It should be noted that I don't really intend to use this device for etching or plating, only for marking. I purchased a really nice 30V DC power supply for etching and plating (shown below). It provides voltage control to ~1/10th volt precision starting from 0V as well as offering control over the max permissable current flow (i.e., amps). It also provides digital voltage and amperage displays to sub-volt precision. However, it doesn't provide AC power. In fact, it's practically impossible to buy an AC power supply since virtually no useful devices run on AC power. I built this device almost exclusively to fill my need for AC power toward the purpose of electro-marking....oh, and it was gobs of fun too.

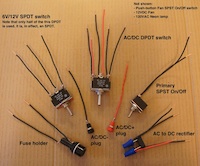

PartsRadio Shack part numbers are included in the parts photo below. I traded out the 24V (12-0-12) transformer from some of the references for a 12V (6-0-6) since I see little need for excessively high voltages (I'll never need 24V anyway) while simultaneously desiring rather low voltages (it'll be nice to get down to 6V, although 0V to 3V might be even more useful, I'm not sure yet (thus I purchased the DC power supply described above)). Both transformers provide a 12V option of course. Note that while I purchased two DPDTs, one acts essentially as an SPDT. Radio Shack didn't have the SPDT in stock, and besides, the DPDT looks nicer; it has a really nice label on the front. Note that I used a slightly different fuse holder than the references. This was originally a mistake; I grabbed the wrong part at Radio Shack. I was about to return it since it's more expensive but then I read the reviews online and people said the intended fuse holder breaks a lot anyway, so I just kept the one I bought. Rather than purchase a power cable, I went to a thrift store with the intention of buying an entire electrical gizmo for less than the price of a new cable and simply cutting the cable off. As it turned out, I found bare cables at the thrift store anyway. Even better. If you do this, make sure you get a three-prong grounded cable, and make sure it's a beefy 10A cable, just to be safe. In summary, I got most of the parts new from Radio Shack, the wire connectors from a local general store (since Radio Shack was staggerly deficient in such items), and as stated, I avoided the $11.00 Radio Shack power cable in favor of a $2.00 thrift store alternative. The fan, push-button switch, and alligator clips were liberated from my electronics odds-n-ends box, the remnants of earlier electronics projects. Final cost including tax was about $70. Pretty silly considering the DC power supply was $60 with all its fine-tuned controls and digital displays...but I need AC for electro-marking! Click to enlarge

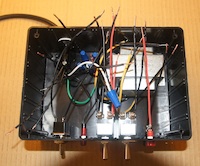

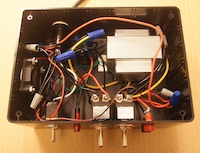

ConstructionVideo demonstrating voltage tests

Results |