Electro-Etching ExperimentsAs of this writing I have only just begun experimenting with electro-etching, -plating, and -marking. I built an electro-etching tool (little more than a power supply), and also use a commercial power supply for similar purposes.

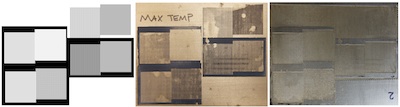

Experiment 1

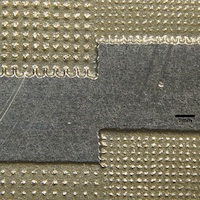

Max temp toner transfer leaves paper residue bonded to the metal (notice the left vs. right halves of the toner transfer photo). The paper residue is not fully etch-transparent (notice that the same region is visible in the etch photo). Final depth is barely perceptible for this voltage, distance, and time.

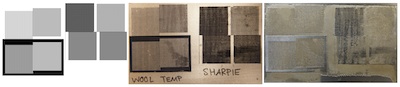

Experiment 2

Final depth is disappointing. Sharpie shows no potential as a resist.

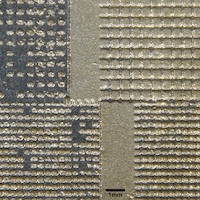

Experiment 3

2.0V proved to be problematic. The current repeatedly decayed due to resistive bubbles forming on the workpiece, thus requiring me to stop the process, remove the workpiece, shake off the bubbles, and resume the process. Over the course of the hour, this problem would occur more and more rapidly. However, the resulting etch was quite impressive. Sub-millimeter features are easily achievable. Although the sharpie left a barely discernable etch-pattern, it nevertheless remains practically useless as a resist in this experiment. Notice that imperfections in the toner transfer are conveyed to the etch with remarkable fidelity.

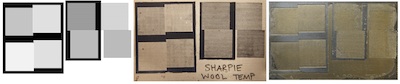

Experiment 4

1.5V offers a good compromise. The current did not decay and therefore I was not required to clean the workpiece throughout the etching process. The resulting depth finally satisfactory, suggesing that etch-times in excess of one hour are required and that the process cannot be adequately sped up by using higher voltages. The details photos are particular impressive. As in experiment 3, features on a sub-millimeter scale are readily achieved. This is also the first experiment in which the sharpie demonstrated a noticable utility as a resist, athough I am displeased with itss lack of precision and general weakness.

The following video walks through the experiments described on this page: |